Haberler

-

Doğru ayna polisini seçmenin önemi ...

Ayna parlatma makineleri, imalat ve bitirme endüstrisinde önemli bir araçtır. Metal, plastik ve hatta cam gibi çeşitli malzemelerde yüksek düzeyde yüzey kaplaması elde etmek ve parlamak için kullanılırlar. Bu blogda, ayna parlatma makinelerinin önemini keşfedeceğiz ve ...Devamını oku -

Ayna parlatma nedir?

Parlatma veya mekanik parlatma olarak da bilinen ayna parlatma, metal bir yüzeyi son derece pürüzsüz ve parlak hale getirmeyi içeren bir işlemdir. Metal parçalar ve bileşenler üzerinde yüksek kaliteli, kusursuz yüzeyler oluşturmak için otomotiv, mücevher ve imalat endüstrilerinde genellikle kullanılır. Goa ...Devamını oku -

Tepsiler basma gizemini bulmak için

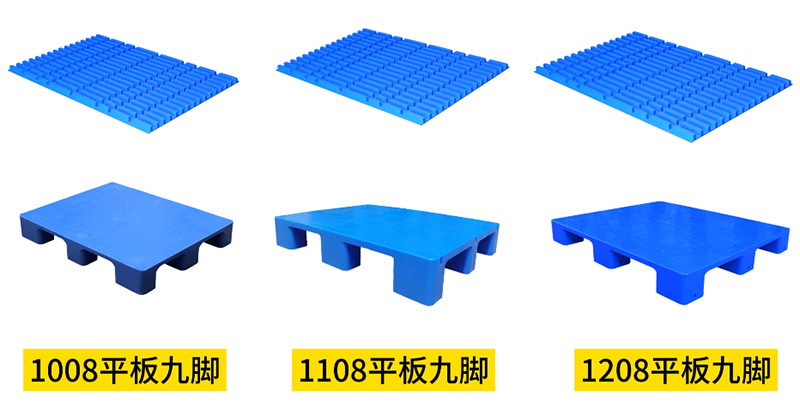

Bugün yivli plastik paletimizi tanıtıyoruz: Palet bir panel, alt plaka ve çelik borudan (gerektiği gibi) oluşuyor. Palet paneli, farklı spesifikasyon ve boyutlarda bir oluk paleti oluşturmak için çeşitli spesifikasyonların ve boyutların düz paletiyle monte edilir. Şekilli oluk palet i ...Devamını oku -

Metal bir deburring makinesinin önemi ...

İmalat endüstrisinde, metal parçalanma süreci metal parçaların kalitesini ve işlevselliğini sağlamak için çok önemlidir. Metal deburring makineleri, keskin kenarları ve çapakları metal parçalardan çıkarmak için tasarlanmıştır, bu da pürüzsüz ve cilalı yüzeylere neden olur. Bu makineler hayati bir r ...Devamını oku -

Düz parlatma makineleri için çözümler

Düz parlatma makineleri, çeşitli endüstrilerde hassas ve yüksek kaliteli yüzey kaplamaları elde etmede çok önemlidir. Bu kapsamlı kılavuz, düz parlatma makineleri, metodolojileri, gelişmiş teknolojileri ve uygulamalarını kapsayan çözümleri araştırıyor. I. Düz po'ya genel bakış ...Devamını oku -

Yüzey tedavisi ve parlatma çözümleri

Yüzey tedavisi ve parlatma, endüstrilerdeki çeşitli malzemelerin estetik çekiciliğini, dayanıklılığını ve işlevselliğini artırmada çok önemli bir rol oynamaktadır. Bu kapsamlı kılavuz, üretim süreçlerinde kullanılan çeşitli yüzey tedavisi ve parlatma çözümlerini araştırarak ...Devamını oku -

Üretim verimliliğinizi bir ADV ...

Günümüzün hızlı tempolu imalat endüstrisinde, maliyetleri en aza indirirken ve verimliliği artırırken yüksek kaliteli ürünler üretmek çok önemlidir. Bu tür operasyonel mükemmelliğe ulaşmanın kritik bir yönü, pürüzlü kenarları, çapakları ve istenmeyen malzemeleri kaldıran bir süreç olan bir süreçtir ...Devamını oku -

Haohan Group, Chine'de önde gelen bir işletme ...

Mükemmellik için çaba göstermeye devam eder ve sürekli teknolojik iyileştirme ihtiyacını tanır. İnovasyon ve kaliteye bağlılıkla, piyasanın gelişen taleplerini karşılamak için metal parlatmada yeteneklerimizi geliştirmeye adadık. Şirketimiz Haohan Group, ...Devamını oku -

Yenilikçi Pil Montaj Çözümleri Revolutio ...

Küresel otomotiv endüstrisi sürdürülebilirliğe doğru dönüştürücü bir değişime maruz kaldıkça, elektrikli araçlara (EV'ler) olan talep arttı ve en son teknolojilerin geliştirilmesine daha fazla önem vermiştir. Bu evrimin ön saflarında, Rea'da öncü bir güç olan Haohan Grubu var ...Devamını oku